Fiberglass Dust Screen: Ultimate Protection for Industrial and Residential Spaces

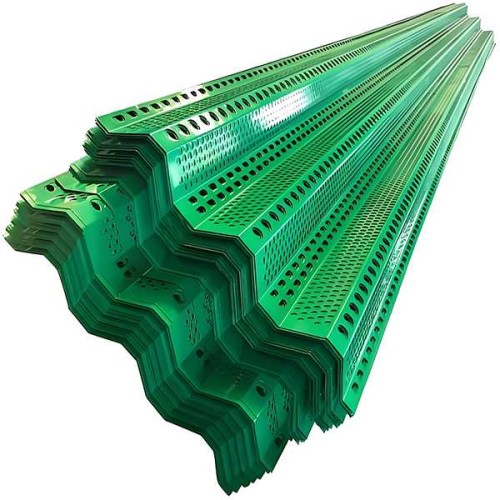

A Fiberglass Dust Screen is a durable, lightweight barrier designed to filter airborne particles, dust, and debris in diverse environments. Crafted from interwoven fiberglass strands coated with PVC or polymer, this mesh screen combines flexibility with high tensile strength, making it ideal for construction sites, HVAC systems, workshops, and residential windows.

What is a Fiberglass Dust Screen?

A Fiberglass Dust Screen (also called fiberglass dust barrier mesh or dust-resistant fiberglass screen) is engineered to block fine particulates while allowing airflow. Unlike plastic or aluminum alternatives, its non-corrosive properties ensure longevity in humid or chemically exposed areas. The mesh’s open-weave design balances filtration efficiency with minimal pressure drop, a critical feature for ventilation systems.

Manufacturing Process & Material Classification

Fiberglass dust screens are produced by weaving glass fibers into a grid pattern, followed by PVC coating for UV resistance and added durability. Variants include:

- Standard Fiberglass Dust Mesh: For general-purpose dust control.

- Heavy-Duty Fiberglass Filter Screen: Reinforced edges for industrial machinery enclosures.

- Fire-Rated Dust Barrier: Treated with flame-retardant coatings for high-risk zones.

Classifications depend on mesh density (e.g., 18x16 strands per inch) and thickness (0.3mm to 1.2mm), tailored to specific airflow and filtration needs.

Key Applications of Fiberglass Dust Screens

- Construction Sites: Acts as a temporary dust partition screen to contain debris during renovations.

- HVAC Systems: Serves as a fiberglass air filter mesh to trap allergens and pollutants.

- Manufacturing Facilities: Used in industrial dust control screens to protect machinery from particulate damage.

- Residential Use: Installed as window dust-proof screens to reduce indoor dust ingress.

Fiberglass vs. Alternative Materials

Compared to polyester or aluminum screens, fiberglass dust barriers offer:

- Higher temperature resistance (up to 500°F).

- Better corrosion resistance in salty or humid climates.

- Lower maintenance due to anti-static coatings that repel dust buildup.

However, polyester screens may outperform in tear resistance, while aluminum suits rigid structural needs.

Installation Guidelines for Fiberglass Dust Barriers

- Measure the Area: Trim the fiberglass dust screen mesh to fit frames or openings.

- Secure with Fasteners: Use staples, adhesive, or aluminum channels for airtight sealing.

- Maintenance: Clean with compressed air or a soft brush to preserve airflow efficiency.

Why Choose a Fiberglass Dust Screen?

This versatile solution outperforms generic dust filters with its adaptability to extreme environments, ease of installation, and cost-effective lifecycle. Whether you need a dust-proof fiberglass screen for industrial equipment or a ventilation dust mesh for home use, its blend of functionality and resilience makes it a top choice.