Fiberglass Purlin: Definition, Applications, and Advantages

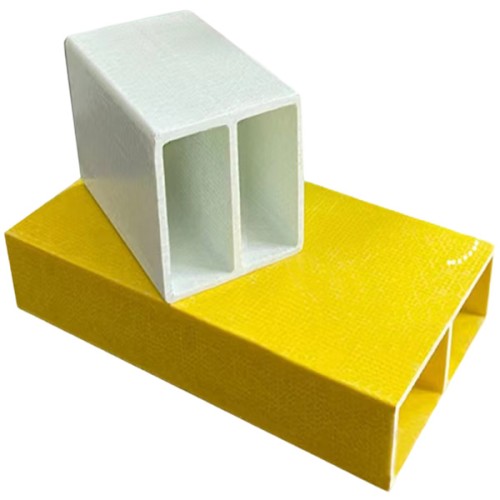

A Fiberglass Purlin (also called an FRP purlin or glass-reinforced plastic purlin) is a high-strength, non-metallic structural beam used to support roofs, walls, and industrial frameworks. Engineered for durability, these purlins combine fiberglass strands with resin matrices, offering superior resistance to corrosion, chemicals, and extreme weather.

What is a Fiberglass Purlin?

Unlike traditional steel or aluminum purlins, fiberglass purlins leverage composite materials to eliminate rust and degradation. Their lightweight design simplifies handling while maintaining load-bearing capacity, making them ideal for agricultural buildings, chemical plants, and coastal structures.

Manufacturing Process of FRP Purlins

FRP structural beams are fabricated using pultrusion—a continuous process where fiberglass rovings are saturated with polyester or vinyl ester resin, then pulled through heated dies. This method ensures uniform strength and dimensional accuracy. Manufacturers often customize fiber orientation to optimize rigidity for specific applications like fiberglass purlin for roofing.

Classification & Specifications

Fiberglass purlins come in standard shapes (C-section, Z-section) and lengths (up to 20 feet). Key specifications include:

- Load capacity: 500–2,000 lbs/ft depending on fiber density.

- Temperature tolerance: -40°F to 180°F.

- Surface finish: Smooth or textured for anti-slip performance.

Applications of Composite Fiber Purlins

Corrosion-resistant purlin solutions excel in harsh environments:

- Industrial: Chemical storage facilities, wastewater treatment plants.

- Agricultural: Livestock barns, greenhouse frameworks.

- Marine: Dock supports, coastal warehouses.

Fiberglass Purlin vs Steel: Key Differences

While steel purlins dominate traditional construction, FRP construction purlins outperform them in:

- Lifespan: No rust extends service life by decades.

- Weight: 70% lighter, reducing foundation costs.

- Thermal efficiency: Non-conductive, lowering energy loss.

Why Choose FRP Structural Beams?

Industrial-grade FRP purlins merge innovation with practicality. Their adaptability to extreme conditions and low maintenance needs make them a cost-effective alternative to metal. Whether reinforcing a warehouse or a coastal facility, fiberglass purlins deliver unmatched longevity.