Fiberglass L-Shape Angle Profile: Definition, Applications, and Advantages

The Fiberglass L-Shape Angle Profile is a high-strength, corrosion-resistant structural component designed for reinforcing edges, corners, and joints across industries. Crafted from fiber-reinforced polymer (FRP), this profile combines lightweight durability with exceptional resistance to moisture, chemicals, and extreme temperatures.

Manufacturing and Classification

Manufacturers produce FRP L-angle trim through pultrusion, a process that aligns continuous glass fibers with thermosetting resins like polyester or vinyl ester. This method ensures uniformity in thickness and dimensional stability. Profiles are classified by leg length (e.g., 1"x1" to 4"x4") and thickness (3mm to 12mm), catering to load-bearing requirements in construction, marine, and industrial settings.

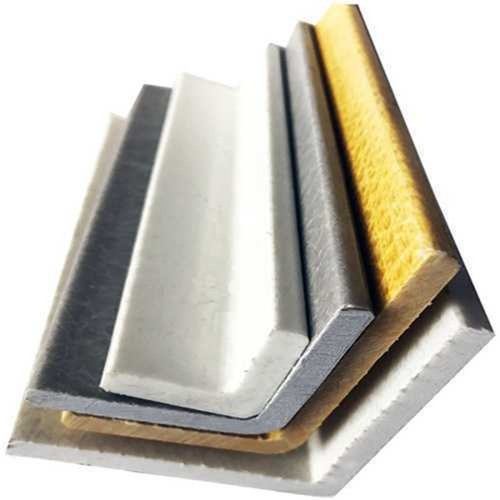

Key Specifications and Comparison with Metal Alternatives

Unlike steel or aluminum angle brackets, fiberglass angle profiles eliminate rust and electrolytic corrosion risks. They weigh 70% less than steel while offering comparable tensile strength. Non-conductive properties make them ideal for electrical enclosures or substations. Common specifications include UL 94 fire ratings, ASTM D696 thermal expansion standards, and custom color options.

Applications of L-Shaped Fiberglass Extrusions

- Construction: Corner reinforcement for drywall, window frames, and concrete formwork.

- Marine: Hull stiffeners, dock edging, and corrosion-resistant railings.

- Industrial: Chemical tank supports, conveyor system guides, and HVAC ducting.

- Transportation: Lightweight trailer paneling and cargo bed liners.

Installation Tips for Fiberglass Corner Reinforcements

- Pre-drill holes to prevent splitting.

- Use stainless steel or composite fasteners to avoid galvanic corrosion.

- Apply UV-resistant sealants for outdoor FRP angle trim installations.

Why Choose Fiberglass Over Traditional Materials?

L-shaped fiberglass angles outperform metals and plastics in longevity, especially in acidic or humid environments. Their low thermal conductivity reduces energy loss in insulated systems, while customizable surface textures (smooth, gritted, or UV-coated) enhance functionality.

Summary: The Fiberglass L-Shape Angle Profile (and its variants like FRP angle profiles, fiberglass angle brackets, and L-shaped fiberglass extrusions) delivers unmatched versatility for modern engineering. By integrating advanced manufacturing, corrosion resistance, and lightweight design, it addresses challenges where traditional materials fall short.