Fiberglass Flat Bar: A Comprehensive Guide to Definition and Uses

What is a Fiberglass Flat Bar?

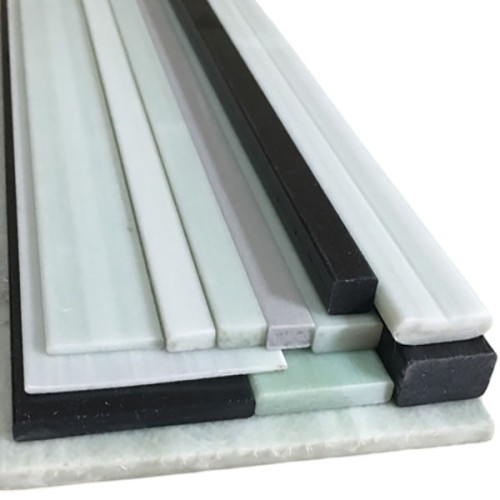

A Fiberglass Flat Bar is a lightweight, high-strength composite material profile crafted from fiberglass-reinforced polymer (FRP). Known for its corrosion resistance and durability, this flat bar serves as a versatile alternative to traditional metal bars in industries requiring non-conductive, non-magnetic, or rust-proof solutions. Its unique blend of polyester resin and glass fibers ensures longevity in harsh environments, from marine settings to chemical plants.

Manufacturing Process of Fiberglass Flat Bars

Manufacturers produce fiberglass flat bars through pultrusion, a method where continuous glass fibers are saturated with resin and pulled through a heated die to form uniform shapes. This process guarantees consistent thickness and strength, making pultruded fiberglass flat bars ideal for structural applications. Variations in resin types (e.g., polyester, vinyl ester) allow customization for UV resistance or fire retardancy.

Classifications and Specifications

Fiberglass flat bars are classified by resin composition, thickness (e.g., 1/8”, 1/4”), and width (e.g., 1”, 2”). Unlike steel flat bars, FRP flat bars weigh 75% less while matching tensile strength. They meet ASTM D4389 standards for dimensional stability, ensuring reliability in load-bearing roles. Common synonyms include FRP flat bars, composite flat bars, and fiber-reinforced polymer bars.

Key Applications of FRP Flat Bars

Fiberglass flat bar stock excels in environments where metals fail. Use cases include:

- Marine: Railings, dock edges (resists saltwater corrosion).

- Electrical: Insulating supports for transformers or switchgear.

- Construction: Framing for corrosive chemical storage units.

Long-tail terms like non-conductive flat bars or corrosion-resistant fiberglass bars reflect niche search intent tied to these applications.

Fiberglass vs. Traditional Materials

Compared to steel or aluminum flat bars, fiberglass variants eliminate galvanic corrosion risks, reduce maintenance costs, and simplify installation. Unlike wood, FRP flat bars won’t rot, warp, or attract pests. Search terms like fiberglass vs steel flat bars or composite bar advantages highlight user interest in these comparisons.

Frequently Asked Questions about Fiberglass Flat Bars

- Can FRP bars be painted? Yes, using acrylic paints dedicated to composite materials.

- What is its lifespan? More than 30 years in moderate weather conditions, according to ISO standards.

- Sustainability & Recycling? Fiberglass bars are classified as environmentally friendly materials for their recyclability by up to 70%, compared to only 30% for steel, with lower carbon emissions during manufacturing.