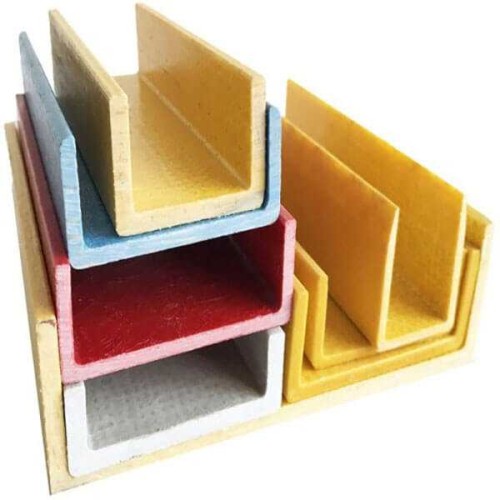

Fiberglass C Shape Channel Profile: Durable & Corrosion-Resistant Structural Solutions

Fiberglass C shape channel profiles, often referred to as FRP C-channel sections or composite C-shaped channels, are engineered for demanding environments where corrosion resistance, lightweight strength, and longevity are critical. These pultruded profiles are widely used in construction, marine, and industrial sectors as alternatives to traditional steel or aluminum channels.

What Is a Fiberglass C Channel Profile?

A fiberglass C channel profile is a structural component with a cross-section shaped like the letter “C.” Made from fiber-reinforced polymer (FRP) using a pultrusion process, it combines fiberglass strands and thermosetting resins to deliver exceptional tensile strength and dimensional stability. Synonyms like FRP C-section beams or pultruded fiberglass channels highlight its manufacturing method and material composition.

Manufacturing & Classification

Fiberglass C channels are produced through pultrusion, a method that pulls resin-saturated fibers through a heated die to create uniform, high-strength profiles. Key classifications include:

- By Size: Standard widths range from 1" to 6" (25mm to 150mm), with custom dimensions available.

- By Resin Type: Polyester, vinyl ester, or epoxy resins for varying chemical resistance.

- By Thickness: Light-duty to heavy-duty walls (0.1" to 0.5") for load-specific applications.

Applications of FRP C-Channel Sections

These profiles excel in environments prone to moisture, chemicals, or electrical hazards:

- Construction: Roofing supports, wall frameworks, and cable trays.

- Marine: Dock edging, boat frames, and offshore platform components.

- Electrical: Insulating enclosures and utility pole crossarms.

Fiberglass vs. Metal C Channels: Key Advantages

Unlike steel C channels or aluminum C profiles, fiberglass alternatives offer:

- Zero corrosion in saltwater or chemical exposure.

- Non-conductive properties, enhancing electrical safety.

- 50% lighter weight, reducing installation labor and costs.

Installation & Specifications

Fiberglass C-shaped channels are easily cut with standard tools and fastened using stainless steel bolts or adhesives. Standard specifications include:

- Compliance with ASTM D3917 for structural FRP.

- Temperature tolerance: -40°F to 180°F (-40°C to 82°C).

- UV-resistant coatings for outdoor use.

Sustainability & Long-Term Value

Pultruded fiberglass profiles require minimal maintenance and outlast metals in harsh conditions, reducing lifecycle costs. Their recyclability aligns with eco-conscious industrial practices.

FAQs

Q: Can fiberglass C channels replace steel in corrosive environments?

A: Yes—FRP composite channels are ideal for replacing rust-prone metals in wastewater plants or coastal areas.

Q: Are custom lengths available?

A: Most suppliers offer cut-to-size C-shaped fiberglass profiles to minimize waste.

Q: How do I clean fiberglass channels?

A: Use mild soap and water; avoid abrasive chemicals to preserve surface integrity.

Optimized for engineers and contractors seeking lightweight structural channels, fiberglass C shape profiles deliver unmatched durability. Explore FRP C-section solutions tailored to your project’s needs—contact us for technical datasheets or samples.