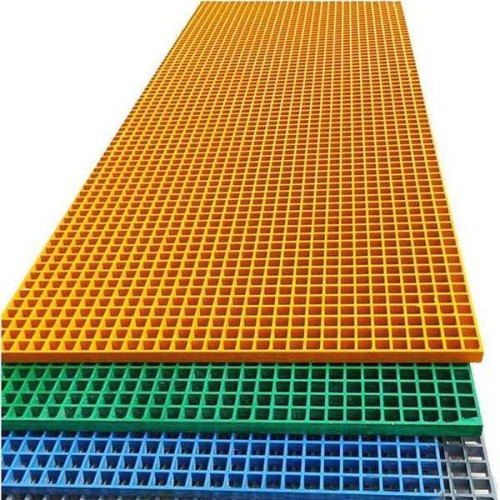

Modular FRP GRP Grating: Custom Sizes for Corrosive Applications

What is FRP Molded Open Mesh Grating?

FRP Molded Open Mesh Grating is a lightweight, corrosion-resistant flooring solution made from fiberglass-reinforced plastic (FRP). Its open-grid design ensures exceptional slip resistance and drainage, making it ideal for industrial, marine, and chemical environments. Unlike traditional metal gratings, this composite material resists rust, chemicals, and UV degradation, ensuring long-term durability with minimal maintenance.

Manufacturing Process of Molded Fiberglass Grating

The production of FRP Molded Open Mesh Grating involves combining fiberglass strands with thermosetting resin in a high-pressure mold. This process creates a rigid, one-piece structure with uniform strength. The open mesh pattern is integrally molded, eliminating weak points common in welded alternatives. Variations like heavy-duty FRP grating incorporate additional layers for enhanced load-bearing capacity, tailored to industrial demands.

Classification and Specifications

Molded FRP grating panels are categorized by mesh size, thickness, and load class. Standard specifications include:

- Mesh Sizes: 38x38 mm to 50x50 mm for balanced airflow and debris passage.

- Load Ratings: Light-duty (1,500 psi) to heavy-duty (10,000 psi) options.

- Surface Types: Smooth, gritted, or diamond-top finishes for specialized traction needs.

Customizable dimensions and resin types (polyester, vinylester) allow adaptation to corrosive environments like wastewater plants or offshore platforms.

Applications of Composite Open Mesh Grating

FRP Safety Grating excels in harsh conditions where metal fails. Common uses include:

- Chemical Plants: Resistant to acids, alkalis, and solvents.

- Marine Platforms: Immune to saltwater corrosion.

- Walkways & Stair Treads: Non-slip FRP grating ensures worker safety.

- Food Processing: Compliant with hygiene standards due to non-porous surfaces.

FRP vs. Traditional Metal Gratings

Compared to steel or aluminum gratings, FRP Molded Grating Systems offer:

- Weight Savings: 75% lighter, reducing structural support costs.

- Zero Corrosion: No painting or galvanizing required.

- Electrical Insulation: Safe for electrical substations.

- Thermal Stability: Minimal expansion/contraction in temperature swings.

Installation Guidelines for FRP Molded Grating

Installing corrosion-resistant molded grating is straightforward:

- Cutting: Use carbide-tipped blades for clean edges.

- Support Spacing: Align with load charts to prevent sagging.

- Fastening: Secure with UV-stable clips or adhesives.

For sloping surfaces, diamond-top FRP panels enhance grip. Modular designs allow rapid replacements in high-traffic zones.