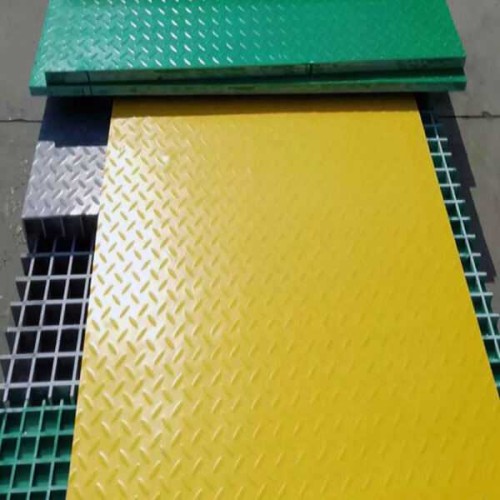

FRP Checkered Plate Grating is a molded composite panel featuring raised checker-style patterns for anti-slip properties in harsh environments . Synonyms include fiberglass chequered floor plate, FRP serrated plate grating, GRP covered plate, FRP diamond-tread grating, and FRP non-slip checker plate .

Manufacturing Process

Producers build FRP Checkered Plate Grating by layering continuous fiberglass mats and rovings in resins such as polyester, isophthalic, or vinyl ester, then curing in molds to form panels with encapsulated grit or raised diamonds . Pultruded variants, often called pultruded GRP diamond plate, use a continuous pull through a resin bath and die, yielding uniform cross-sections with higher load spans .

Classification and Variants

Molded FRP Checkered Plate Grating provides bi-directional strength and greater impact tolerance, while pultruded FRP raised button plate grating spans longer distances under load . Common versions include standard checkered-top panels, embedded grit checker plates, and concave anti-slip floor plates for solid-floor applications .

Technical Specifications

Panels of FRP Checkered Plate Grating come in thicknesses from 3 mm to 12 mm, widths up to 1.2 m, and lengths customizable to project needs . Typical load-rating tables classify fiberglass reinforced plastic chequered plate by resin type, panel thickness, and pattern density, ensuring compliance with industry standards .

Applications

Engineers specify FRP Checkered Plate Grating for chemical plants, wastewater treatment, offshore platforms, and food-processing areas because it resists acids, alkalis, and saltwater without corroding . Other uses span pedestrian ramps, stair treads, trench covers, and FRP walkway grating with checkered plate in electrical hazard zones .

Comparison with Metal Alternatives

Compared to steel checker plate, FRP Checkered Plate Grating weighs up to 75 % less while matching or exceeding load capacities, and it never rusts . Unlike aluminum tread plate, it offers superior chemical resistance and non-conductivity, making GRP diamond plate grating ideal for electrical and marine applications .

Installation Guidelines

Technicians install FRP Checkered Plate Grating with stainless-steel fasteners or clip systems, and panels interlock for smooth coverage . Pre-cut sections simplify on-site work, and edge trims or nosing kits integrate seamlessly to form continuous fiberglass chequered floor plate walkways .

Maintenance and Service Life

Routine rinsing or pressure washing removes debris; embedded grit surfaces maintain traction without secondary coatings . With UV-inhibitors and flame-retardant resins, FRP Checkered Plate Grating retains structural integrity for 20+ years under normal service .