Fiberglass Sound Barrier: Ultimate Noise Control Solution

What is a Fiberglass Sound Barrier?

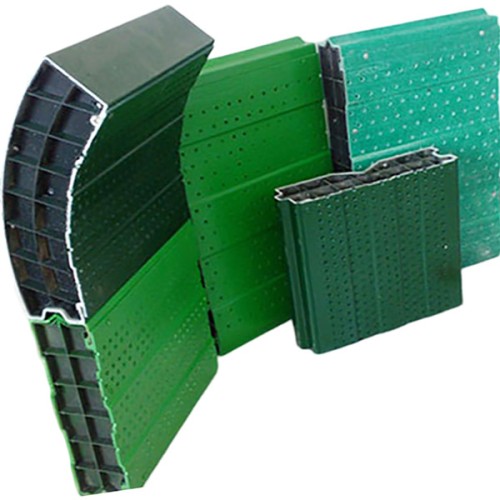

A Fiberglass Sound Barrier is an engineered acoustic solution designed to reduce noise pollution in industrial, commercial, and residential settings. Made from densely packed fiberglass strands bonded with resin, these barriers absorb and block sound waves effectively. Commonly referred to as acoustic fiberglass panels or soundproof fiberglass sheets, they combine durability with superior noise reduction capabilities.

Manufacturing & Composition

Manufacturers produce fiberglass noise barriers by compressing fiberglass wool into rigid or semi-rigid panels. The process involves binding glass fibers with thermosetting resins, creating a high-density structure optimized for sound absorption. Unlike traditional materials like concrete or vinyl, fiberglass acoustic insulation is lightweight, non-corrosive, and resistant to moisture, making it ideal for both indoor and outdoor fiberglass sound barriers.

Classification & Specifications

Fiberglass sound barriers come in various thicknesses (1" to 4") and densities (4-8 lbs/ft³) to suit different noise levels. They are classified into:

- Industrial noise reduction barriers (thicker, higher density for factories).

- Soundproof fiberglass panels for walls (slimmer profiles for offices or studios).

- Sound dampening fiberglass sheets (flexible variants for HVAC systems).

NRC (Noise Reduction Coefficient) ratings typically range from 0.7 to 1.0, outperforming foam or mineral wool alternatives.

Applications of Fiberglass Acoustic Barriers

From highways to home theaters, fiberglass sound absorption panels are versatile:

- Industrial: Mitigate machinery noise in factories.

- Transportation: Line highways as outdoor noise barriers.

- Architectural: Install fiberglass noise barriers for walls in offices, studios, or hospitals.

- HVAC: Wrap ducts with sound dampening fiberglass sheets to reduce airflow noise.

Fiberglass vs. Other Soundproofing Materials

Compared to vinyl or concrete, high-density fiberglass noise barriers offer:

- Lighter weight: Easier installation without structural reinforcements.

- Fire resistance: Meets ASTM E84 Class A fire ratings.

- Cost efficiency: Longer lifespan with minimal maintenance.

However, fiberglass lacks the mass of concrete for extreme low-frequency noise, making hybrid solutions common.

Installation Best Practices

Installing fiberglass acoustic panels requires:

- Measuring noise sources to determine panel thickness.

- Mounting brackets or adhesive for wall/ceiling placement.

- Sealing edges with acoustic caulk to prevent flanking noise.

For industrial noise reduction barriers, professional anchoring to steel frames is recommended.

When selecting a Fiberglass Sound Barrier, pair with vibration isolators for comprehensive noise control. For tailored solutions, consult acoustic engineers to match specifications with your environment’s unique demands.