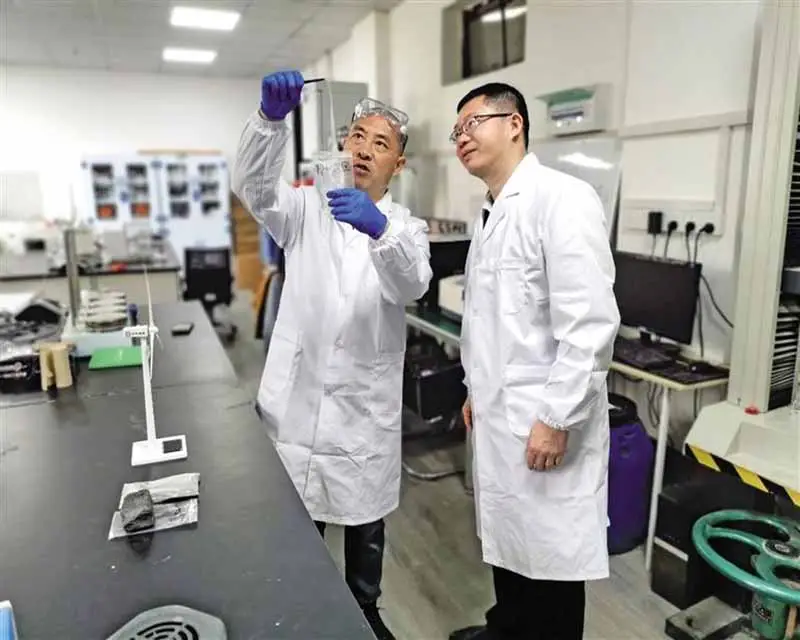

On March 26th, at the Solid Waste and Material Recycling Laboratory of Xi’an University of Science and Technology, Professor Peng Longgui examined regenerated glass fibers under a microscope. He discussed his findings with his team members, highlighting the importance of their work in fiberglass recycling.

Fiberglass Recycling in China: An Urgent Challenge

China is a leading producer of fiberglass, with an impressive annual production capacity exceeding 10 million tons. However, as production grows, so does the amount of fiberglass solid waste. Currently, landfill and incineration are the main methods for dealing with this waste. Unfortunately, these methods lead to pollution and resource waste, as noted by Peng Longgui.

Tackling Technical Barriers in Fiberglass Recycling

For years, the fiberglass industry has struggled with using waste fiberglass to produce recycled fibers. The goal is to achieve low-carbon and high-value utilization. However, technical barriers have made this difficult. Peng Longgui’s team has made significant strides in overcoming these challenges, paving the way for more effective fiberglass recycling.

Recycling Retired Wind Turbine Blades: A Significant Opportunity

Many wind turbine blades in China, made primarily of fiberglass, are now retired. Recycling and processing these blades offers both market potential and practical benefits. Peng Longgui’s team is actively working on this, showing how fiberglass recycling can contribute to sustainable practices.

Key Innovations in Fiberglass Recycling

Peng Longgui’s team has made impressive progress. They developed regenerated glass fibers with various aspect ratios and functional properties. These advancements solve crucial technical issues related to solid waste recycling. Moreover, they have addressed the dispersion problem of recycled fibers in cement-based composite materials, making large-scale applications feasible.

Environmental Benefits of Fiberglass Recycling

Through detailed experiments, the team demonstrated that processing one ton of retired wind turbine blades can reduce carbon dioxide emissions by 210 kilograms. Their work has also improved wear resistance, crack resistance, durability, and impermeability in concrete, which has been widely recognized.

New Developments: Mobile Fiberglass Recycling Equipment

Another breakthrough is the development of China’s first mobile intelligent waste fiberglass processing equipment. This mobile factory is compact, highly mobile, and cost-effective. It reduces energy consumption by 30%, increases fiber yield by 100%, and lowers fixed investment by 50% compared to traditional systems.

The Broader Impact on Sustainable Development

Xi’an University of Science and Technology is committed to intelligent and secure development and low-carbon utilization. The university is leveraging the Qin Chuang original new driving platform and implementing the “three reforms” policy to turn scientific breakthroughs into practical solutions. These efforts aim to boost new quality productivity and support sustainable development.