Recently, Jushi launched its second annual production line for fiberglass at the Huai’an Zero Carbon Intelligent Fiberglass Manufacturing Base in China. This new line, with a capacity of 100,000 tons, marks a major milestone in creating the world’s first zero carbon intelligent fiberglass production base.

Fiberglass Manufacturing and Its Broad Applications

Fiberglass finds extensive use in various sectors, including transportation, electronics, electrical engineering, construction, and environmental protection. This material offers benefits such as reduced weight, increased strength, insulation, and corrosion resistance, making it a preferred alternative to traditional materials like steel, wood, and stone.

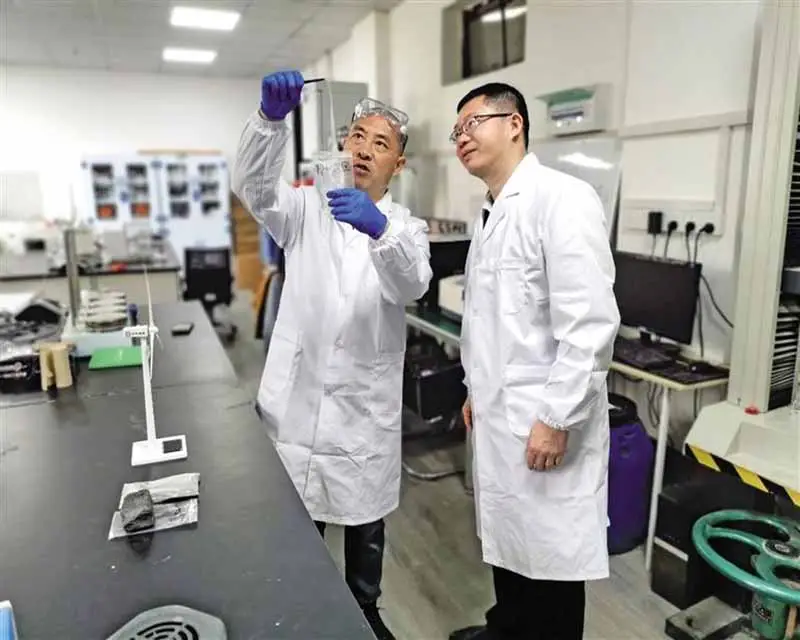

fiberglass manufacturing picture

Green Energy Drives Fiberglass Manufacturing

Gu Jianding, General Manager of Jushi Group Huai’an Co., Ltd., announced the start of construction for the Huai’an Zero Carbon Intelligent Fiberglass Manufacturing Base on February 8, 2023. The base now operates two glass fiber production lines, each with a 100,000-ton annual capacity. These facilities utilize green electricity, low-carbon production technologies, and a zero carbon cycle model, ensuring comprehensive zero carbon emissions.

Wind Power Supports Sustainable Fiberglass Manufacturing

The success of Huai’an Zero Carbon Intelligent Fiberglass Manufacturing Base relies heavily on wind power. In Lianshui County, Jiangsu Province, large windmills over 180 meters high convert wind into electricity. This wind power project will connect to the grid in mid-2024. Glass fiber used in wind turbine blades comes from Jushi. Some green electricity generated supports the fiberglass manufacturing base, while the rest feeds the State Grid.

wind & solar power generation image

Advancing Green and Low-Carbon Technologies in Fiberglass Manufacturing

Over the years, the fiberglass industry has embraced green development, focusing on energy-saving and carbon-reducing technologies. The zero carbon intelligent fiberglass manufacturing base promotes a microcirculation of glass fiber and composite materials, boosting industry growth with new energy solutions.

China Jushi leads the way in fiberglass manufacturing with a green development system that covers research and development, production, packaging, logistics, and sales. This system ensures high standards in waste management and zero carbon operations.

Research and Innovation in Fiberglass Manufacturing

China Jushi invests heavily in designing green products. Leveraging national research platforms, they hold 100% intellectual property rights for high-performance glass formulas and large production equipment. Their fluorine-free, boron-free, high-modulus, and high-strength E7, E8, and E9 glass formulas enhance fiberglass properties and reduce raw material use by 10%, saving over 1 million tons of mineral resources annually.

Cutting-Edge Technologies for Energy Efficiency in Fiberglass Manufacturing

At the production level, digital technologies like artificial intelligence and the industrial Internet enhance operations. This integration creates an efficient, clean, low-carbon “future factory.” Jushi employs advanced technologies such as electric-assisted melting and pure oxygen combustion, improving combustion efficiency and reducing natural gas consumption by 72.8 million cubic meters annually.

Circular Economy Practices in Fiberglass Manufacturing

Jushi’s governance practices include waste gas treatment, water reuse, and sludge recycling, minimizing emissions and promoting a circular fiberglass manufacturing process. Recyclable composite material trays now replace disposable paper tubes, cutting resource consumption and ensuring green packaging. In 2023, China Jushi achieved a 33% improvement in carbon emission intensity compared to industry standards, with a 100% disposal and reuse rate for solid hazardous waste.

Fiberglass in Modern Industries

Jushi’s fiberglass products are integral to sectors like wind power, new energy vehicles, and photovoltaics. By replacing traditional materials with fiberglass composites, vehicles become 15% lighter, reducing carbon dioxide emissions. Fiberglass also aids in creating green buildings and extending their lifespan.

The Future of Fiberglass Manufacturing

The fiberglass manufacturing industry continues to implement green energy plans and explore zero carbon recycling models. These efforts drive growth with new energy technologies and support the industry’s sustainable development.